High-Quality Truck Mirrors for Sale in China

By:Admin

With a focus on meeting the demands of the modern trucking industry, China Truck Mirror has invested heavily in research and development, leading to the creation of advanced mirror designs that cater to the specific needs of commercial trucks and heavy-duty vehicles. These mirrors are engineered to provide optimal visibility and safety for drivers, contributing to the overall efficiency and effectiveness of truck operations.

One of the key features of China Truck Mirror's products is their durability and resistance to environmental factors. Designed to withstand the rigors of long-haul transportation, these mirrors are constructed using high-quality materials that are capable of withstanding extreme weather conditions and rough handling. This ensures that the mirrors remain functional and reliable throughout their lifespan, reducing the need for frequent replacements and maintenance.

In addition to their robustness, the mirrors produced by China Truck Mirror are also equipped with advanced technology that enhances their performance. This includes features such as anti-glare coatings, wide-angle lenses, and adjustable positioning, all of which contribute to improved visibility and safety for truck drivers. Furthermore, the incorporation of innovative materials and manufacturing processes has resulted in mirrors that are lighter in weight without compromising on strength, contributing to fuel efficiency and overall vehicle performance.

Furthermore, China Truck Mirror has demonstrated its commitment to sustainability by implementing eco-friendly practices in its production processes. The company has invested in state-of-the-art facilities that prioritize energy efficiency and waste reduction, minimizing its environmental impact. By adopting sustainable manufacturing practices, China Truck Mirror is not only contributing to the global effort to reduce carbon emissions but also ensuring that its products align with the evolving environmental standards and regulations.

The dedication of China Truck Mirror to excellence extends beyond its products to its customer service and support. The company has established a strong network of distributors and service centers, ensuring that customers have access to reliable technical assistance and prompt delivery of spare parts. This commitment to customer satisfaction has earned China Truck Mirror a solid reputation in the industry, with a growing customer base that extends across the globe.

As a result of its continuous advancements in product development and production technology, China Truck Mirror has positioned itself as a leading supplier of truck mirrors in the global market. With a strong focus on quality, innovation, and sustainability, the company is well-equipped to meet the evolving needs of the automotive industry and maintain its position as a trusted partner for commercial truck operators and vehicle manufacturers.

Looking ahead, China Truck Mirror is poised to continue its trajectory of growth and success, driven by its relentless pursuit of excellence and its commitment to meeting the demands of a rapidly evolving market. With a strong foundation built on advanced technology, durability, and customer satisfaction, the company is well-positioned to maintain its leadership in the automotive industry and set new standards for truck mirror technology.

Company News & Blog

Discover the Latest Innovations in Plastic Injection Molding Machines

[Title]: Plastic Injection Molding Machine: Revolutionizing Manufacturing Processes[Subtitle]: [Company Name]: Leading the Way with Cutting-Edge Technology[Company Introduction][Company Name] is a global leader in manufacturing state-of-the-art plastic injection molding machines. Since its inception in [year], the company has been at the forefront of technological innovation, constantly pushing boundaries and setting new industry standards. With a commitment to providing high-quality machines that deliver exceptional performance, [Company Name] has become a trusted partner for numerous industries across the globe.[Paragraph 1]Plastic injection molding machines have become an integral part of various manufacturing processes, enabling efficient and cost-effective production of plastic components. The advancements in technology have revolutionized the industry, and [Company Name] has been at the forefront of these innovations. The company's dedication to research and development has resulted in cutting-edge machines that offer unmatched precision, speed, and reliability.[Paragraph 2]One of the key highlights of [Company Name]'s plastic injection molding machines is their versatility. With a wide range of models available, the machines cater to the diverse needs of different industries, including automotive, consumer goods, electronics, medical, and packaging. These machines can handle a vast array of materials, from traditional thermoplastics to advanced composites, allowing manufacturers to produce components with intricate designs and complex geometries.[Paragraph 3]The success of injection molding lies in its ability to deliver consistently high-quality parts with minimal waste. In this aspect, [Company Name] has perfected its machines to optimize production efficiency while ensuring exceptional product quality. Through advanced automation and control systems, these machines offer real-time monitoring and precise control of parameters such as temperature, pressure, and injection speed. This level of control not only leads to higher productivity but also minimizes defects, thus reducing waste and increasing cost-effectiveness.[Paragraph 4]Noteworthy is [Company Name]'s commitment to sustainability. Environmental consciousness and responsible manufacturing have become a priority in today's world, and [Company Name] has recognized this need. The plastic injection molding machines designed by the company incorporate energy-efficient technologies, reducing power consumption and minimizing the carbon footprint. By employing features like variable pump systems and servo motors, these machines contribute to a greener and more sustainable manufacturing industry.[Paragraph 5]In addition to the cutting-edge technology incorporated into their machines, [Company Name] also offers comprehensive customer support. From initial consultation to after-sales service, the company's dedicated team of experts ensures a smooth and hassle-free experience for every customer. By providing training, technical assistance, and spare parts availability, [Company Name] establishes long-lasting partnerships with its clients, fostering trust and loyalty.[Paragraph 6]Looking ahead, [Company Name] continues to invest heavily in research and development, further propelling the industry with innovative solutions. With rapid advancements in materials and manufacturing techniques, plastic injection molding machines will continue to play a pivotal role in meeting the ever-evolving demands of the market. [Company Name]'s commitment to staying ahead of the curve ensures that manufacturers across the world can rely on their machines to achieve exceptional results while staying competitive in today's fast-paced manufacturing landscape.[Conclusion]Plastic injection molding machines have revolutionized the manufacturing industry, and [Company Name] has been at the forefront of this revolution. By consistently delivering cutting-edge technology, exceptional performance, and comprehensive customer support, [Company Name] has established itself as a global leader in the field. With an unwavering commitment to sustainability and a focus on staying ahead of industry trends, [Company Name] continues to shape the future of plastic injection molding, offering manufacturers the tools they need to excel in their respective industries.

Ultimate Guide to Injection Molding: Everything You Need to Know

Injection molding is a manufacturing process used to produce products in large quantities, and it has become an essential part of the production process for many companies. With the increasing demand for high-quality, cost-effective products, injection molding has become a popular choice for manufacturers across various industries.In recent news, {Company} has announced the expansion of their injection molding capabilities to better serve their customers. This expansion comes as a response to the growing demand for their products, and it will allow {Company} to increase their production capacity and improve their overall efficiency.{Company} is a leading manufacturer in the industry, and they have built a reputation for delivering top-quality products to their customers. With the expansion of their injection molding capabilities, {Company} aims to further solidify their position as a reliable and innovative manufacturer in the market.Injection molding is a versatile process that allows manufacturers to create a wide range of products, including automotive parts, medical devices, consumer goods, and more. The process involves injecting molten material into a mold, which is then cooled and solidified to form the final product. This method is highly efficient and cost-effective, making it an attractive option for manufacturers looking to produce large quantities of high-quality products.The expansion of {Company}'s injection molding capabilities will allow them to meet the growing demand for their products while maintaining their commitment to excellence. By investing in the latest technology and equipment, {Company} is positioning themselves to stay ahead of the competition and continue to deliver exceptional products to their customers.{Company} has a team of experienced professionals who are dedicated to providing custom solutions to their clients' needs. With the expanded injection molding capabilities, {Company} will be able to offer even more options for customization and product development, allowing them to better serve their diverse customer base.In addition to the expansion of their injection molding capabilities, {Company} is also committed to sustainability and environmental responsibility. They are constantly seeking ways to minimize waste and reduce their environmental impact, and the new injection molding equipment is designed with efficiency and waste reduction in mind.{Company} is excited to bring these new capabilities to the market and looks forward to the opportunities that this expansion will bring. They are confident that the investment in their injection molding capabilities will allow them to better serve their customers and continue to be a leader in the industry.Overall, the expansion of {Company}'s injection molding capabilities is a significant step forward for the company and the industry as a whole. By investing in the latest technology and equipment, {Company} is positioning themselves to meet the growing demand for their products while maintaining their commitment to excellence and sustainability. As they continue to grow and evolve, {Company} remains dedicated to providing top-quality products and custom solutions to their customers.

Top 10 Best LED Headlamps You Need for Your Outdoor Adventures

In recent years, advances in technology have revolutionized the automotive industry, leading to an increased demand for innovative and high-quality vehicle components. One such component that has seen significant advancements is the headlamp. The headlamp is an essential part of any vehicle, providing illumination for the driver to see the road ahead and for other road users to see the vehicle. With the growing emphasis on safety and performance, the importance of high-quality headlamps cannot be overstated. One company that has been at the forefront of developing cutting-edge headlamp technology is [Company Name]. With a focus on innovation and excellence, [Company Name] has established itself as a leader in the automotive lighting industry.Founded in [Year], [Company Name] has a long history of delivering top-of-the-line lighting solutions for vehicles of all types. The company prides itself on its commitment to research and development, consistently pushing the boundaries of what is possible in automotive lighting. This dedication to innovation has led to the creation of some of the most advanced headlamp technologies available on the market today.One of the key features that set [Company Name] apart from its competitors is its use of state-of-the-art LED technology in its headlamp designs. LED (light-emitting diode) headlamps offer numerous advantages over traditional halogen lamps, including greater energy efficiency, longer lifespan, and enhanced illumination. [Company Name] has been at the forefront of incorporating these benefits into its headlamp designs, setting new standards for performance and reliability.In addition to LED technology, [Company Name] has also been a pioneer in implementing advanced control systems in its headlamp designs. The company's headlamps are equipped with sophisticated sensors and adaptive lighting features, allowing for optimal visibility in all driving conditions. This level of intelligence and adaptability is a reflection of [Company Name]'s unwavering commitment to safety and performance.Furthermore, [Company Name] places a strong emphasis on design aesthetics, ensuring that its headlamps not only perform exceptionally but also enhance the overall look of the vehicle. The company's team of designers and engineers work tirelessly to strike the perfect balance between form and function, resulting in headlamp designs that are as visually striking as they are functional.As the automotive industry continues to evolve, [Company Name] remains at the forefront of innovation, constantly pushing the boundaries of what is possible in automotive lighting. The company's commitment to excellence and its unwavering dedication to safety and performance make it a trusted partner for both vehicle manufacturers and consumers alike.The future of automotive lighting is bright, and [Company Name] is leading the way with its state-of-the-art headlamp technology. With a focus on innovation, performance, and design, [Company Name] is set to continue shaping the future of automotive lighting for years to come.

Discover the Latest Rear Light Options for Your Vehicle

Title: Advanced Rear Light Enhancement Technology Pioneered by Leading Automotive Accessories ProviderIntroduction:In a groundbreaking technological advancement, a renowned automotive accessories provider is introducing an innovative rear light enhancement solution that is set to revolutionize road safety. This cutting-edge technology not only significantly improves visibility but also enhances the overall aesthetics of vehicles. Developed with a perfect amalgamation of form and function, this rear light system ensures enhanced safety on the roads, setting a new standard for automotive accessories.Company Background:Before delving into the specifics of this groundbreaking rear light technology, it is imperative to understand the company behind its development. As a leading automotive accessories provider, the company has been at the forefront of designing and manufacturing high-quality vehicle accessories for years. With a dedicated team of experts and state-of-the-art research and development facilities, they have consistently provided innovative solutions tailored to meet the ever-evolving needs of the automotive industry.Article:It is no secret that road safety is a pressing concern, with accidents often arising due to poor visibility, particularly during adverse weather conditions or at night. Recognizing this critical issue, the company has invested substantial resources in developing an advanced rear light enhancement system that promises to significantly improve visibility for all road users.The newly developed rear light system incorporates a series of sophisticated features that work together seamlessly to provide enhanced safety on the roads. These features include:1. Innovative Light Emitting Diodes (LEDs): The rear light system incorporates advanced LED technology that ensures superior brightness and visibility, making it easier for other motorists and pedestrians to spot the vehicle even from a distance. The LEDs are meticulously arranged to optimize light distribution and effectiveness.2. Adaptive Lighting: The rear light system intelligently adjusts its brightness according to the prevailing lighting conditions. This feature prevents glare for drivers following behind while ensuring maximum visibility for the vehicle itself. The adaptive lighting system also helps reduce driver fatigue and eye strain during nighttime drives.3. Dynamic Signal Lights: Another notable feature of this rear light system is the incorporation of dynamic signal lights. Unlike conventional static signal lights, these dynamic lights have a built-in sequence pattern that visually communicates the driver's intentions with exceptional clarity. Pedestrians and fellow motorists can easily interpret the signals, leading to improved safety on the roads.4. Robust Design: The rear light system has been designed to withstand the harshest environmental conditions, ensuring longevity and durability. The materials used are of the highest quality, rendering the system resistant to water, dust, and vibrations. This ensures consistent performance and longevity, even in challenging terrains or adverse weather.Furthermore, this rear light system is compatible with various vehicle models, making it a versatile solution for a wide range of vehicles on the road. Vehicle owners will also appreciate the ease of installation, as the system can be seamlessly integrated into the existing rear light housing.In addition to its advanced technological features, this rear light system boasts an aesthetically pleasing design that complements the overall look of the vehicle. The sleek and modern design elements align seamlessly with the vehicle's contours, adding a touch of sophistication and elegance to its appearance.The company's commitment to safety and innovative design is evident in their rear light enhancement technology. By prioritizing both functionality and appearance, this rear light system sets a new standard for automotive accessories, redefining road safety expectations. Whether driving on poorly lit roads, during inclement weather, or in heavy traffic, vehicle owners can rely on this cutting-edge solution to significantly improve their visibility and reduce the risk of accidents.Conclusion:Through its tireless dedication to developing innovative solutions, this leading automotive accessories provider has pioneered a game-changing rear light enhancement system that promises to revolutionize road safety. By incorporating advanced LED technology, adaptive lighting, and dynamic signal lights, this rear light system provides enhanced visibility and safety while maintaining a sleek and stylish design. With its versatility and durability, this groundbreaking technology is set to become an essential accessory for all vehicle owners, ensuring a safer and more aesthetically appealing driving experience for all.

A Complete Guide to Reviewing Car Mirrors: What to Look For

Car Review Mirror recently completed a comprehensive review of the latest car mirror technology, highlighting the impressive features and benefits of the company’s innovative products. With a focus on enhancing safety and convenience for drivers, the brand has solidified its position as a leading provider of top-quality car mirrors.Established in [year], [company name] has been dedicated to producing high-quality car mirrors that prioritize safety, innovation, and style. With a commitment to excellence and customer satisfaction, the company has continuously set new industry standards for car mirror technology.The review by Car Review Mirror recognized [company name]'s commitment to staying at the forefront of technological advancements in the automotive industry. The company's mirrors were lauded for their advanced features, including integrated blind spot detection, auto-dimming capabilities, and sleek, modern designs. These features not only enhance the overall driving experience but also contribute to a safer driving environment for all road users.One of the key highlights of [company name]'s car mirrors is their innovative blind spot detection system, which has been designed to alert drivers of potential hazards in their vehicle's blind spots. This feature has been praised for its effectiveness in reducing the risk of accidents and improving overall road safety. Additionally, the auto-dimming capabilities of the mirrors have been noted for their ability to reduce glare from headlights, resulting in improved visibility and reduced eye strain for drivers.Furthermore, the review emphasized the aesthetically pleasing designs of [company name]'s car mirrors, which seamlessly integrate modern style with practical functionality. The sleek and minimalist designs not only enhance the overall look of the vehicle but also contribute to improved aerodynamics and fuel efficiency.In addition to their advanced features and stylish designs, [company name]'s car mirrors were also commended for their durability and reliability. The company takes pride in using high-quality materials and state-of-the-art manufacturing processes to ensure that their products meet the highest standards of performance and longevity.As a leading provider of car mirrors, [company name] has continuously demonstrated its commitment to customer satisfaction through its dedication to innovation, safety, and quality. The company's products have been widely recognized for their ability to enhance the driving experience while prioritizing the safety of drivers and passengers.Looking ahead, [company name] remains focused on furthering its advancements in car mirror technology, with a continued emphasis on innovation, safety, and customer satisfaction. By staying at the forefront of the automotive industry, the company is poised to maintain its position as a leader in the market for high-quality car mirrors.In conclusion, the review by Car Review Mirror reaffirmed [company name]'s status as a top provider of innovative and high-quality car mirrors. With a strong focus on safety, innovation, and style, the company continues to set new standards for excellence in the automotive industry. As drivers increasingly prioritize safety and advanced technology in their vehicles, [company name] remains well-positioned to meet and exceed their expectations with its cutting-edge car mirrors.

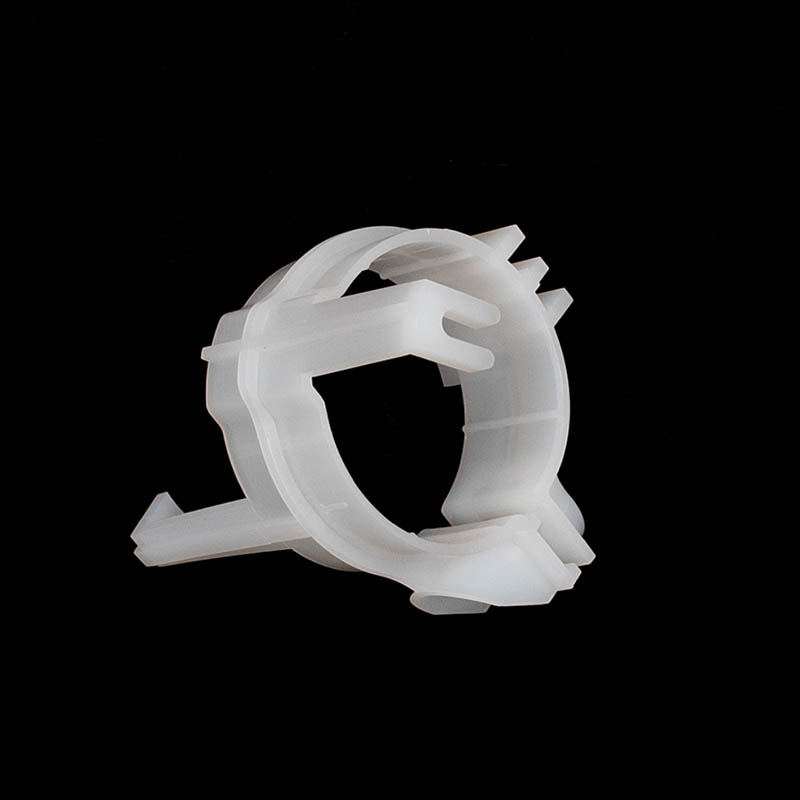

Quality Plastic Injection Molding Parts for Your Business Needs

Plastic Injection Molding Parts has been an essential part of manufacturing processes for many industries around the world. It is a cost-effective and efficient method for producing a wide range of plastic parts and components. The process involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape.One company that has been at the forefront of plastic injection molding is {}. They have established themselves as a leading provider of high-quality plastic injection molding parts for various industries. With their state-of-the-art manufacturing facilities and a team of skilled engineers and technicians, they have been able to meet the diverse needs of their customers and deliver top-notch products consistently.{} is committed to delivering innovative solutions and superior products to their clients. Their expertise in plastic injection molding allows them to cater to a wide range of industries, including automotive, aerospace, electronics, medical, and consumer goods. Their comprehensive range of services includes product design and development, prototype testing, mold making, and mass production. They work closely with their clients to understand their specific requirements and ensure that the final products meet their expectations.The company's manufacturing facilities are equipped with the latest in plastic injection molding technology, including high-precision molds and advanced machinery. This allows them to produce complex parts with tight tolerances and high-quality surface finishes. Their manufacturing processes are optimized for efficiency and cost-effectiveness, allowing them to deliver products on time and within budget.{} has a strong focus on quality assurance and has implemented a rigorous quality control system to ensure that all products meet the highest standards. They utilize advanced inspection and testing equipment to verify product quality and performance, and they adhere to strict quality management practices. This commitment to quality has earned them a reputation for reliability and excellence in the industry.In addition to their technical capabilities, {} places a strong emphasis on sustainability and environmental responsibility. They are committed to reducing waste and minimizing the environmental impact of their operations. They employ eco-friendly manufacturing processes and materials whenever possible, and they continuously seek ways to improve their sustainability practices.The company's dedication to innovation and customer satisfaction has earned them a strong reputation in the industry. They have built long-term partnerships with a diverse clientele, providing them with tailored solutions and exceptional products. {} is renowned for its responsiveness, flexibility, and ability to meet the most demanding requirements.Looking to the future, {} remains committed to driving innovation and delivering value to its customers. With a focus on continuous improvement and investment in cutting-edge technology, they strive to stay ahead of the curve and maintain their position as a leader in plastic injection molding.As the demand for high-quality plastic injection molding parts continues to grow, {} is well-positioned to meet the needs of a diverse range of industries. Their dedication to excellence, innovative approach, and commitment to sustainability make them a trusted partner for companies seeking top-notch plastic injection molding solutions.In conclusion, Plastic Injection Molding Parts is a critical aspect of modern manufacturing, and {} stands as a leader in providing high-quality, innovative solutions to their clients. With a strong focus on quality, sustainability, and customer satisfaction, they have solidified their position as a go-to provider for plastic injection molding parts. Their commitment to excellence and their ability to meet the most challenging requirements make them a valuable partner for companies seeking reliable and cost-effective plastic injection molding solutions.

Top Plastic CNC Machining Prototype Services for Precision Engineering

CNC plastic machining is an essential process in the manufacturing industry, and [Company Name] has established itself as a leader in producing high-quality CNC plastic machining prototypes. With their state-of-the-art equipment and experienced team, [Company Name] has been successfully providing top-notch CNC plastic machining services to various industries.At [Company Name], they understand the importance of prototyping when it comes to product development. Having a precise and accurate prototype is crucial in the testing and validation phase of product development. This is where their CNC plastic machining prototype services come in, allowing their clients to have a tangible representation of their product design.The CNC plastic machining process at [Company Name] involves the use of computer numerical control (CNC) machines to precisely cut and shape plastic materials according to the client's specifications. The company prides itself on its ability to produce complex and intricate designs with incredible accuracy and speed. This is made possible by their team of skilled machinists and engineers who are experts in CNC plastic machining.One of the key advantages of choosing [Company Name] for CNC plastic machining prototypes is their ability to work with a wide range of plastic materials. Whether it's ABS, polycarbonate, acrylic, or any other type of plastic, [Company Name] has the expertise and capabilities to machine it with precision. This versatility allows their clients to explore different material options for their prototypes and test how each material performs in real-world conditions.Furthermore, [Company Name] strives to provide quick turnaround times for their CNC plastic machining prototypes. They understand the urgency of product development and are committed to delivering prototypes in a timely manner. This quick response time enables their clients to move swiftly through the product development process and make necessary iterations to their designs.In addition to their CNC plastic machining capabilities, [Company Name] also offers a range of finishing services to ensure that the prototypes meet the highest standards. Whether it's sanding, polishing, or painting, [Company Name] can provide the necessary finishing touches to enhance the appearance and functionality of the prototypes.The CNC plastic machining prototypes produced by [Company Name] have been utilized in a variety of industries, including automotive, aerospace, medical, and consumer goods. The precision and quality of their prototypes have helped their clients in testing and refining their product designs, ultimately leading to successful product launches.With their commitment to excellence and customer satisfaction, it's no wonder that [Company Name] has earned a stellar reputation in the CNC plastic machining industry. The company's dedication to precision, quality, and efficiency has set them apart as a trusted partner for businesses looking to bring their product designs to life.As the demand for high-quality prototypes continues to rise, [Company Name] remains at the forefront of CNC plastic machining, offering innovative solutions and superior craftsmanship. Their ability to consistently deliver exceptional prototypes has solidified their position as a go-to provider for CNC plastic machining services.In conclusion, [Company Name] is a leading provider of CNC plastic machining prototypes, offering unparalleled expertise, a wide range of material options, quick turnaround times, and top-notch finishing services. Their commitment to excellence and dedication to customer satisfaction make them the ideal partner for businesses in need of high-quality prototypes for product development. With [Company Name], clients can have confidence in the precision and reliability of their CNC plastic machining prototypes, knowing that they are in capable hands.

Top Plastic Machining Prototype Techniques for CNC Manufacturing

In the world of manufacturing, precision and accuracy are paramount, and having the right tools and technology at your disposal can make all the difference. That's why the team at [Company Name] in [Location] has announced the launch of their latest CNC plastic machining prototype, setting a new standard for precision in the industry.With over [number] years of experience in the manufacturing and machining industry, [Company Name] has established itself as a leader in delivering high-quality, highly-precise components for a wide range of applications. Their team of skilled engineers and technicians are dedicated to providing innovative solutions that meet the unique needs of their clients, and the introduction of this new CNC plastic machining prototype further cements their commitment to excellence.The new CNC plastic machining prototype boasts cutting-edge technology and state-of-the-art features that set it apart from traditional machining methods. With its advanced computer numerical control (CNC) system, the prototype offers unmatched precision and accuracy, allowing for the production of complex and intricate plastic components with ease. This level of precision is crucial for industries such as aerospace, automotive, medical, and electronics, where even the slightest deviation from specifications can have serious consequences.One of the key advantages of the new CNC plastic machining prototype is its ability to handle a wide range of plastic materials, including but not limited to, acrylic, ABS, nylon, polycarbonate, and polyethylene. This versatility ensures that [Company Name] can accommodate the diverse needs of their clients and provide them with custom solutions that are tailored to their specific requirements.In addition to its precision and versatility, the CNC plastic machining prototype also offers increased efficiency and productivity. The automated nature of the CNC system allows for faster production times and reduced waste, ultimately leading to cost savings for clients. This is particularly important in today's highly competitive market, where companies are constantly seeking ways to optimize their manufacturing processes and improve their bottom line.Furthermore, the CNC plastic machining prototype also enables [Company Name] to offer rapid prototyping services, allowing clients to quickly and cost-effectively test new designs and concepts before moving into full-scale production. This not only accelerates the product development cycle but also minimizes the risk of costly errors and setbacks down the line."We are thrilled to introduce our new CNC plastic machining prototype to the market," said [Spokesperson], [Title] at [Company Name]. "This innovative technology represents a significant advancement in our capabilities, allowing us to deliver even higher levels of precision, quality, and efficiency to our clients. We believe that this new prototype will be a game-changer for the industries we serve, and we are excited about the opportunities it will bring."The launch of the new CNC plastic machining prototype reaffirms [Company Name]'s position as a leading provider of advanced manufacturing solutions. By continuously investing in technology and expertise, they have consistently raised the bar for quality and performance, earning the trust and loyalty of their clients across the globe.As [Company Name] continues to push the boundaries of what is possible in the world of CNC plastic machining, they remain committed to innovation, excellence, and exceeding the expectations of their clients. With the new prototype now available, they are poised to further solidify their reputation as a trusted partner for precision manufacturing needs.In conclusion, the introduction of the new CNC plastic machining prototype from [Company Name] represents a significant milestone in the industry, showcasing their dedication to pushing the boundaries of what is possible in precision manufacturing. With its advanced technology, versatility, and efficiency, the prototype is set to revolutionize the way plastic components are produced, setting a new standard for excellence in the field. As [Company Name] continues to innovate and excel, they are well-positioned to meet the evolving needs of their clients and make a lasting impact in the world of manufacturing.

How Injection Moulding is Revolutionizing Manufacturing

Injection Moulding, the process of injecting molten material into a mould to create a variety of products, has revolutionized the manufacturing industry. This efficient and cost-effective method has allowed companies to produce high-quality goods at a rapid pace. One company at the forefront of this industry is {Company Name}, a leading manufacturer of injection moulding machinery.{Company Name} has been a pioneer in the injection moulding industry for several decades. With state-of-the-art technology and a team of experienced professionals, they have consistently delivered top-of-the-line machinery to their clients. Their commitment to innovation and customer satisfaction has solidified their reputation as a trusted partner for companies around the globe.The injection moulding machines manufactured by {Company Name} are designed to meet the diverse needs of their clients. Whether it's producing small, intricate parts or large, complex components, their machinery is equipped to handle a wide range of manufacturing requirements. Their dedication to precision and efficiency has made them a preferred choice for companies in industries such as automotive, medical, packaging, and consumer goods.In addition to their cutting-edge machinery, {Company Name} also offers comprehensive support and services to their clients. From initial consultation and planning to installation and maintenance, they ensure that their customers have a seamless experience from start to finish. Their commitment to quality and reliability has earned them long-standing partnerships with some of the biggest names in manufacturing.One of the key advantages of {Company Name}'s injection moulding machines is their ability to enhance production efficiency. By streamlining the manufacturing process and minimizing waste, their machinery helps companies reduce costs and increase their overall productivity. This has a direct impact on their clients' bottom line, making {Company Name} an invaluable asset to their business operations.Furthermore, {Company Name} is dedicated to sustainability and environmentally-friendly practices. Their injection moulding machines are designed to minimize energy consumption and material waste, helping companies reduce their carbon footprint. By prioritizing eco-friendly solutions, they are not only contributing to a cleaner planet but also helping their clients meet their sustainability goals.As the demand for high-quality manufactured goods continues to grow, {Company Name} remains committed to staying ahead of the curve. They are constantly investing in research and development to improve their machinery and introduce new technologies. This dedication to innovation ensures that their clients have access to the latest advancements in injection moulding, allowing them to stay competitive in the market.With a global presence and a track record of excellence, {Company Name} is well-positioned to meet the evolving needs of the manufacturing industry. Their unwavering commitment to quality, reliability, and customer satisfaction sets them apart as a leader in the injection moulding sector. By providing cutting-edge machinery and exceptional support, they have become a trusted partner for companies looking to elevate their manufacturing capabilities.In conclusion, Injection Moulding has become an indispensable process for companies across various industries, and {Company Name} has emerged as a driving force in this field. With their advanced machinery, commitment to sustainability, and dedication to innovation, they continue to set the standard for excellence in injection moulding. As the manufacturing industry continues to evolve, {Company Name} is poised to lead the way with their innovative solutions and unwavering commitment to their clients' success.

Exploring the Outstanding Properties of Aluminum Alloy – A Game-Changer in Several Industries

[Company Name] Launches Innovatively Engineered Aluminum Alloy for High-Performance Applications[City, Date] - [Company Name], a leading innovator in material science and engineering, has unveiled its latest breakthrough in aluminum alloy technology. The company's cutting-edge alloy promises to revolutionize the industry with its superior strength, lightweight properties, and exceptional performance characteristics. This new development is set to have far-reaching implications in various sectors, including aerospace, automotive, construction, and consumer electronics.[Company Name] has been at the forefront of materials research and development for over two decades. With a strong focus on innovation and sustainability, the company has consistently produced groundbreaking solutions that cater to the evolving needs of its clients. This latest aluminum alloy is no exception. Its unique composition and manufacturing process result in a material that surpasses the traditional limitations of aluminum, offering enhanced strength, durability, and corrosion resistance.One of the standout features of this new aluminum alloy is its remarkable strength-to-weight ratio. Engineers and designers can now create structures and products that are both lightweight and exceptionally strong. This characteristic makes it an ideal choice for applications that demand high-performance and reliable materials. Additionally, the alloy's excellent fatigue resistance ensures longevity, making it a cost-effective solution in the long run.The aerospace industry, in particular, stands to benefit greatly from [Company Name]'s groundbreaking innovation. The alloy's superior strength and lightweight properties provide crucial advantages in aircraft construction, where weight reduction is of utmost importance for fuel efficiency and increased payload capacity. It also exhibits exceptional corrosion resistance, ensuring the longevity and safety of critical aircraft components.The automotive industry is another area where the new alloy can make a significant impact. As the demand for electric vehicles continues to rise, lightweight materials are essential to maximize battery efficiency and extend driving range. [Company Name]'s aluminum alloy offers automakers the perfect solution, enabling them to reduce vehicle weight without compromising structural integrity or safety.In the construction sector, this alloy presents exciting possibilities for designers and architects. Its high strength and durability make it an ideal choice for structural components, allowing for more creative and efficient designs. Additionally, the lightweight nature of the alloy simplifies installation processes and reduces construction time and costs.Consumer electronics manufacturers stand to benefit from the alloy's desirable properties as well. From smartphones to laptops and wearables, lightweight materials are increasingly sought after for their portability and aesthetic appeal. [Company Name]'s aluminum alloy provides a durable and visually pleasing solution, accommodating the demand for sleek and slim designs without compromising device performance.Furthermore, the alloy's environmental advantages are of paramount importance in today's world. It boasts a lower carbon footprint compared to traditional materials, thanks to its recyclability and energy-efficient manufacturing process. This aligns with [Company Name]'s commitment to sustainability and ensures that the new alloy meets the growing demands of eco-conscious industries.In conclusion, [Company Name]'s groundbreaking aluminum alloy marks a significant advancement in material science. With its exceptional strength, lightweight properties, and environmental benefits, the alloy has the potential to reshape various industries. Whether it's in aerospace, automotive, construction, or consumer electronics, the applications of this innovative alloy are limitless. [Company Name] continues to drive the boundaries of material technology, cementing its position as a leader in the field.