Welding of Large Carbon Steel Structural Parts: Everything You Need to Know

By:Admin

{} specializes in the fabrication and welding of large carbon steel structural parts, catering to the needs of various industries including oil and gas, construction, and infrastructure development. Their team of skilled welders and engineers are highly experienced in working with carbon steel, ensuring that each project meets the highest standards of quality and durability.

Recently, {} was commissioned to undertake the welding of large carbon steel structural parts for a major infrastructure project. This project required the welding of intricate parts that would form the backbone of a massive bridge, and the client turned to {} due to their track record of delivering high-quality welding services.

The welding process for large carbon steel structural parts is a complex and critical task, as the integrity and strength of the welds are crucial to the overall structure. {} employs a range of advanced welding techniques, including gas metal arc welding (GMAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW), to ensure that the welds meet the required specifications and standards.

In addition to their welding expertise, {} has also invested in state-of-the-art welding equipment to support their operations. This includes advanced welding machines, positioners, and manipulators that enable their team to work efficiently and accurately on large-scale projects. Furthermore, their fabrication facility is equipped with the latest technology to handle the cutting, shaping, and assembly of carbon steel structural parts with precision and accuracy.

With a strong focus on safety and quality, {} adheres to strict welding procedures and industry standards to ensure that the final product meets all necessary requirements. Their team undergoes regular training and certification to stay updated on the latest welding techniques and best practices, further validating their commitment to delivering superior welding services.

In addition to their expertise in welding, {} also provides comprehensive project management and logistical support to ensure that their clients' needs are met on time and within budget. Their dedication to customer satisfaction has earned them a loyal clientele who continue to rely on {} for their welding and fabrication needs.

As the demand for large carbon steel structural parts continues to grow, {} remains at the forefront of the industry, leading the way with their innovative approach and unwavering commitment to excellence. Their track record of successful projects, combined with their extensive experience and expertise, positions them as a top choice for companies requiring welding services for large-scale structural components.

In conclusion, the welding of large carbon steel structural parts is a critical process that requires precision, expertise, and advanced equipment. With over three decades of experience in the industry, {}, has established itself as a leader in providing high-quality welding and fabrication services. Their commitment to excellence, safety, and customer satisfaction makes them a trusted partner for companies undertaking large-scale construction and infrastructure projects.

Company News & Blog

Discover High-Quality Auto Body Parts for Efficient Repairs

Title: Auto Body Part Manufacturer Delivers High-Quality Products With Exceptional DurabilityIntroduction:Auto Body Part, a reputable manufacturer in the automotive industry, has gained recognition for its commitment to producing top-quality and durable vehicle components. With a focus on delivering superior performance and excellent customer service, the company has become a trusted provider of auto body parts for numerous automobile brands across the globe.Body:(Paragraph 1)Auto Body Part has established itself as a leading manufacturer in the highly competitive automotive parts market. The company's mission is to provide auto body parts that meet or exceed the industry standards for quality, performance, and durability. Through continuous research and development, they have been able to create advanced manufacturing processes and invest in state-of-the-art machinery, ensuring the production of superior products.(Paragraph 2)One of Auto Body Part’s key strengths lies in its team of highly skilled engineers and technicians. Their expertise is invaluable in developing and perfecting cutting-edge manufacturing techniques, allowing the company to deliver stylish and functional auto body parts that enhance the overall appearance and performance of vehicles. This attention to detail has earned the trust of customers worldwide.(Paragraph 3)Auto Body Part is known for its comprehensive range of auto body parts, catering to a diverse array of vehicle models. Whether it is a bumper, fender, grille, or other exterior components, their products seamlessly fit various automobile brands without compromising the integrity of the original design. Customers can rely on the precise fit and finish of Auto Body Part’s offerings, ensuring a seamless replacement and enhanced aesthetic appeal.(Paragraph 4)Another notable aspect of Auto Body Part’s operations is their unwavering commitment to quality control. Each product undergoes rigorous testing procedures to ensure its durability, resistance to corrosion, and compliance with safety regulations. By adhering to strict quality control measures, the company ensures that their auto body parts are not only visually appealing but also meet the highest industry standards.(Paragraph 5)In addition to providing top-quality auto body parts, Auto Body Part also emphasizes excellent customer service. Their knowledgeable and friendly customer support team assists clients throughout the purchasing process, addressing any queries and concerns promptly. The company believes in building long-term relationships with its customers by providing a seamless experience, from initial inquiries to after-sales support.(Paragraph 6)Auto Body Part’s commitment to sustainability is evident in their approach to manufacturing. The company incorporates eco-friendly practices in its operations, reducing waste and minimizing environmental impact. By adhering to responsible manufacturing practices, Auto Body Part not only contributes to a greener future but also sets an example for other industry players to follow.(Paragraph 7)Moreover, Auto Body Part has made significant investments in research and development to stay updated with the latest industry trends and emerging technologies. By continuously improving their products, the company ensures that they are at the forefront of innovation, offering auto body parts that exceed customer expectations.(Paragraph 8)Auto Body Part's dedication to excellence has earned them several industry accolades and certifications. These recognitions serve as a testament to their commitment to delivering superior products and exceptional customer service. It is through their relentless pursuit of quality and innovation that Auto Body Part has become a trusted name in the automotive parts industry.Conclusion:Auto Body Part has established itself as a reputable manufacturer in the automotive industry, delivering high-quality and durable auto body parts. With a focus on innovation, precision, and exceptional customer service, Auto Body Part continues to exceed customer expectations while contributing to a more sustainable future. Their commitment to excellence sets the benchmark for the industry, making them the go-to choice for automobile enthusiasts and professionals alike.

Aluminum Part Manufacturer Unveils Innovative Product for Enhanced Performance

[Header][Date][Headline]Aluminum Part Revolutionizes Manufacturing Industry[Subtitle]Company [Company Name] Introduces an Innovative Aluminum Part that Enhances Efficiency and Durability[Location] – In a groundbreaking development, [Company Name], a leading manufacturer in the industrial sector, has unveiled a state-of-the-art aluminum part that is set to revolutionize the manufacturing industry. With its unique design and advanced features, this new aluminum component promises to greatly enhance production efficiency, durability, and overall performance for a wide range of applications.[Paragraph 1]Over the years, aluminum has become the preferred material in various industries due to its exceptional qualities, including lightweight properties, high strength-to-weight ratio, and excellent corrosion resistance. Recognizing the immense potential of aluminum, [Company Name] has dedicated significant resources to develop an aluminum part that surpasses existing market standards.[Paragraph 2]The newly developed aluminum component, whose branding will be removed for editorial purposes, is set to disrupt existing manufacturing practices. Engineered with utmost precision and integrity, this aluminum part boasts a number of groundbreaking features that offer unparalleled advantages to the end-user.[Paragraph 3]One of the key highlights of this innovative aluminum part is its superior structural integrity. Through advanced manufacturing techniques and rigorous quality control measures, [Company Name] has achieved a product that ensures remarkable durability and longevity. This means reduced maintenance costs and increased productivity for manufacturers across various sectors.[Paragraph 4]The unique design of the aluminum part also addresses common challenges faced by manufacturers, such as cumbersome installation processes and compatibility issues. With its user-friendly interface and flexible installation options, this aluminum component seamlessly integrates into existing systems, allowing for hassle-free upgrades and greatly minimizing downtime for production facilities.[Paragraph 5]Moreover, the improved efficiency provided by this aluminum part enables manufacturers to enhance their competitive edge. By reducing energy consumption, optimizing production cycles, and streamlining overall operations, companies can achieve significant cost savings while also minimizing their environmental impact. This development underlines [Company Name]'s commitment to sustainable manufacturing practices.[Paragraph 6]In addition to its superior performance, the aluminum part also offers a wide range of customization options to suit the specific needs of different industries. [Company Name] ensures that its clients can tailor the component according to their requirements, whether it be for automotive, aerospace, construction, or any other sector that relies on top-quality aluminum parts.[Paragraph 7][Company Name]'s cutting-edge aluminum part has already garnered significant praise from industry experts. By leveraging its extensive research and development capabilities, combined with its commitment to unparalleled quality standards, the company has succeeded in pushing the boundaries of what aluminum can achieve in the manufacturing sector.[Paragraph 8]The launch of this revolutionary aluminum part highlights [Company Name]'s ongoing dedication to technological innovation, aiming to drive progress and improve the overall performance of the manufacturing industry. With its proven track record and commitment to customer satisfaction, [Company Name] has solidified its position as a trusted name in providing superior aluminum solutions.[Quote]"[Company Name] is proud to introduce this game-changing aluminum part to the market," says [Spokesperson's Name], a representative of the company. "Our team has worked tirelessly to develop a product that exceeds expectations, revolutionizing the way manufacturers operate. This aluminum part will undoubtedly deliver exceptional value to our customers."[Paragraph 9]As the global manufacturing industry continues to evolve, innovations such as [Company Name]'s aluminum part pave the way for enhanced efficiency, durability, and sustainability. With this groundbreaking development, businesses across sectors can confidently embrace the future of manufacturing, knowing they have a reliable and high-performing aluminum component at their disposal.[Closing]For more information on [Company Name] and its groundbreaking aluminum part, please visit [Company Website].

Maximizing Efficiency and Precision: Exploring the Benefits of Metal Stamping Parts

Metal Stamping Part: Revolutionizing the Manufacturing IndustryIn the ever-evolving world of manufacturing, metal stamping has emerged as a game-changer for the industry. Offering precision, efficiency, and cost-effectiveness, metal stamping has revolutionized the production of various components, allowing companies to meet the demands of a rapidly changing market.Metal stamping involves the process of shaping and forming metal sheets into desired shapes and sizes. This manufacturing technique utilizes a highly specialized machinery known as a stamping press, which applies pressure to the metal sheet, thereby imprinting the desired design. This process has been widely adopted by numerous industries, including automotive, aerospace, electronics, and many more.One company at the forefront of the metal stamping revolution is {}. With decades of experience in the industry, they have established themselves as a leading manufacturer of metal stamping parts. Committed to delivering excellence and innovation, they have captured the attention of both domestic and international clients.Using state-of-the-art technology and machinery, {} is able to produce metal stamping parts with unparalleled precision and accuracy. By leveraging the expertise of their highly skilled engineers and technicians, they have successfully developed a wide range of components that cater to the diverse needs of their customers.The advantages of metal stamping are manifold. Firstly, this manufacturing technique allows for the production of parts with high dimensional accuracy, ensuring a seamless fit in the final product. This precision is crucial in industries such as automotive and aerospace, where even the slightest deviation can lead to catastrophic consequences.Secondly, metal stamping offers great efficiency in terms of production speed. With the ability to produce thousands of parts per hour, manufacturers can meet large-scale demands without compromising on quality. This increased efficiency has significantly reduced production times and costs, giving companies a competitive edge in today's fast-paced market.Furthermore, metal stamping enables the production of complex and intricate designs that would be otherwise unattainable through traditional manufacturing methods. This versatility allows designers and engineers to explore new possibilities and push the boundaries of innovation.Another notable advantage of metal stamping is its cost-effectiveness. By utilizing high-speed stamping presses and automated production lines, manufacturers can achieve economies of scale, thereby reducing production costs. This cost reduction is crucial for businesses aiming to stay competitive in an increasingly price-sensitive market.As society becomes more environmentally conscious, metal stamping also offers environmentally friendly benefits. The high level of efficiency and precision in metal stamping minimizes material waste, conserving resources and reducing the carbon footprint of manufacturing processes. Additionally, the use of recyclable materials further contributes to a sustainable production cycle.Looking towards the future, metal stamping is poised to undergo further advancements. With ongoing research and development efforts, manufacturers are continually improving the capabilities of their stamping presses, resulting in even higher levels of precision, efficiency, and versatility.In conclusion, metal stamping has revolutionized the manufacturing industry by providing precision, efficiency, and cost-effectiveness. Companies like {} have played a pivotal role in driving this revolution, offering high-quality metal stamping parts to a wide range of industries. As the industry continues to evolve, metal stamping will undoubtedly play a vital role in shaping the future of manufacturing.

Top Plastic Home Appliances for Modern Living

Home Appliance Plastic, a leading provider of high-quality and innovative plastic components for home appliances, has been making waves in the industry with its latest product offerings and technology advancements. With a commitment to delivering exceptional performance and reliability, Home Appliance Plastic has solidified its position as a trusted partner for leading home appliance manufacturers globally.The company's dedication to excellence is evident in its state-of-the-art manufacturing facilities and cutting-edge technologies that enable the production of superior quality plastic components. From refrigerator shelves and door bins to dishwasher racks and panels, Home Appliance Plastic offers a comprehensive range of products that are designed to meet the rigorous demands of the home appliance industry.One of the key differentiators of Home Appliance Plastic is its unwavering focus on innovation and sustainability. The company continually invests in research and development to explore new materials and manufacturing processes that not only improve the performance of its products but also reduce their environmental impact. This commitment to sustainability is reflected in the company's efforts to incorporate recycled and bio-based materials into its product lines, as well as its initiatives to optimize energy efficiency and minimize waste in its production processes.In addition to its dedication to quality and sustainability, Home Appliance Plastic places a strong emphasis on collaboration and customer satisfaction. The company works closely with its clients to understand their specific needs and challenges, leveraging its expertise to develop customized solutions that address their requirements. Whether it's a specialized component for a new appliance model or a modification to an existing product, Home Appliance Plastic is committed to delivering the best possible outcomes for its customers.Furthermore, Home Appliance Plastic is not just a supplier of plastic components, but a strategic partner that provides value-added services such as design engineering, prototyping, and supply chain management. By offering end-to-end support, the company ensures that its clients have access to the resources and expertise they need to bring their products to market efficiently and effectively.As the demand for energy-efficient and sustainable home appliances continues to grow, Home Appliance Plastic is well-positioned to meet the evolving needs of the industry. The company's forward-thinking approach and dedication to innovation have enabled it to stay ahead of industry trends and deliver cutting-edge products that align with the latest market requirements.In the coming years, Home Appliance Plastic aims to further expand its product portfolio and enhance its capabilities to cater to the ever-changing needs of the home appliance industry. By staying true to its core values of quality, sustainability, and customer focus, the company is poised to continue its success and make a lasting impact on the home appliance market.With a strong track record of delivering exceptional products and services, Home Appliance Plastic is a trusted partner for home appliance manufacturers seeking high-quality plastic components. The company's unwavering commitment to innovation, sustainability, and customer satisfaction sets it apart as a leader in the industry, and its future looks bright as it continues to drive positive change in the home appliance market.

Guide to Choosing the Right Car Lights for Optimal Visibility

Car Lights Revolutionizes the Automotive Lighting Industry with Innovative Solutions[City], [Date] - Car Lights, a leading player in the automotive lighting industry, is set to revolutionize the sector with its cutting-edge technologies and forward-thinking approach. With a strong focus on innovation and customer satisfaction, Car Lights is poised to become the go-to company for state-of-the-art automotive lighting solutions.Car Lights understands that lighting plays a crucial role in ensuring the safety and performance of vehicles on the road. As such, the company is committed to offering high-quality lighting products that not only enhance visibility but also provide a sense of style and elegance to automobiles.With an extensive range of products, Car Lights caters to all automotive lighting needs, including headlights, tail lights, fog lights, and interior lights. The company prides itself on its diverse collection of lighting options, catering to different models and brands of vehicles.One of Car Lights' flagship products is its revolutionary LED headlights. These headlights offer unparalleled brightness and clarity, ensuring a safer and more enjoyable driving experience. LED headlights are known for their energy efficiency, longevity, and superior illumination, making them an ideal choice for today's environmentally conscious consumers.Car Lights' LED headlights are designed with precision to ensure a perfect fit for various vehicle models. The company's dedicated research and development team works tirelessly to stay ahead of the curve, incorporating the latest technological advancements into their products. Furthermore, Car Lights' LED headlights come with easy installation features, allowing consumers to effortlessly upgrade their existing lighting systems.In addition to its wide range of lighting products, Car Lights also offers customized lighting solutions to meet the specific needs and preferences of its customers. The company understands that every individual has different tastes and requirements when it comes to automotive lighting. Therefore, Car Lights provides personalized options, enabling customers to create a unique and visually striking lighting configuration for their vehicles.Car Lights puts utmost importance on customer satisfaction. The company believes in fostering long-term relationships with its clients and aims to provide exceptional after-sales support. The customer service team at Car Lights is always ready to assist customers with any queries or concerns they may have regarding their products or installation process. Moreover, the company offers warranties on its products, giving customers peace of mind and confidence in their purchases."As technology evolves, so does the automotive lighting industry," says [Company Founder/CEO]. "At Car Lights, we strive to be at the forefront of this evolution, consistently offering innovative lighting solutions that meet the evolving demands of our customers. We are committed to pushing boundaries and setting new standards in the industry."Car Lights has already gained recognition for its excellence in the automotive lighting sector. The company has earned multiple awards and accolades for its innovative products and dedication to customer satisfaction. By combining cutting-edge technologies, exceptional design, and a customer-centric approach, Car Lights has set itself apart from competitors.Looking ahead, Car Lights is actively investing in research and development to bring even more advanced lighting solutions to the market. The company is focused on exploring emerging technologies such as adaptive headlights, augmented reality lighting displays, and eco-friendly lighting options. By pushing the boundaries of innovation, Car Lights aims to contribute to a safer and more sustainable future for the automotive industry.About Car Lights:Car Lights is a leading player in the automotive lighting industry. With a commitment to innovation and customer satisfaction, Car Lights offers a wide range of high-quality lighting products, including LED headlights, tail lights, fog lights, and interior lights. The company prides itself on its personalized lighting solutions and exceptional after-sales support. Car Lights is dedicated to pushing boundaries and setting new standards in the industry by combining cutting-edge technologies with exceptional design.

Durable Plastic Handle Grips for a Secure Grip

The plastic grip is an essential accessory for a wide range of tools and equipment. From hand tools to sports equipment, the plastic grip plays a crucial role in providing a comfortable and secure handle for users. One company that has been at the forefront of manufacturing high-quality plastic grips for various applications is [Company Name].[Company Name] is a leading manufacturer and supplier of plastic grips for a diverse range of products. With years of experience and expertise in the industry, the company has built a solid reputation for providing top-notch plastic grips that are durable, ergonomic, and high-performing.The company offers a wide range of plastic grips to cater to the unique needs of different industries and applications. Whether it's for hand tools, power tools, gardening equipment, or sports gear, [Company Name] has the expertise and capabilities to design and produce custom plastic grips that meet the specific requirements of its clients.One of the key products in [Company Name]'s portfolio is the plastic handle grip, which is widely used in hand tools such as screwdrivers, pliers, hammers, and more. These handle grips are designed to provide a comfortable and secure grip for users, allowing them to work more efficiently and safely.The plastic handle grips from [Company Name] are made from high-quality materials that are resistant to wear and tear, chemicals, and extreme temperatures. This ensures that the grips can withstand the rigors of daily use in various working environments, making them a reliable choice for professionals and DIY enthusiasts alike.In addition to their durability, the plastic handle grips from [Company Name] are also designed with ergonomics in mind. The company understands the importance of providing users with a comfortable and fatigue-free grip, which is why its handle grips are designed to fit the natural shape of the hand, reducing strain and discomfort during prolonged use.Furthermore, [Company Name] takes pride in its ability to customize plastic handle grips to meet the unique specifications of its clients. Whether it's a specific color, size, shape, or texture, the company has the expertise and resources to design and produce custom handle grips that align with its clients' exact requirements.Aside from hand tools, [Company Name] also supplies plastic handle grips for a wide range of other applications, including sports equipment such as bicycle handlebars, golf club handles, and fitness equipment grips. The company's versatile manufacturing capabilities allow it to cater to the diverse needs of different industries, delivering high-quality plastic grips that enhance the performance and comfort of various products.With a strong commitment to quality and customer satisfaction, [Company Name] has established itself as a trusted partner for businesses looking for reliable and high-performing plastic grips. The company's dedication to innovation and continuous improvement ensures that its products meet the highest standards and deliver exceptional value to its clients.In conclusion, the plastic handle grip from [Company Name] is a testament to the company's expertise and commitment to excellence in manufacturing plastic grips. With a focus on durability, ergonomics, and customizability, the company has positioned itself as a leading supplier of plastic grips for a wide range of applications. Whether it's for hand tools, sports equipment, or any other product that requires a secure and comfortable handle, [Company Name] has the capabilities to design and deliver top-quality plastic grips that meet its clients' specific needs.

Top 5 Essential Metal Fabrication Services You Need to Know

[News Headline]Innovative Metal Fabrication Solutions Revolutionizing Industrial Manufacturing[News Introduction]Metal fabrication, a crucial aspect of industrial manufacturing, is undergoing a transformative phase with ground-breaking solutions developed by a renowned company. This company, a leader in the field of metal fabrication, has introduced remarkable advancements that are revolutionizing the industry. With a focus on precision engineering, efficiency, and sustainability, their cutting-edge technologies are set to redefine the way metal components and structures are manufactured. This article will delve into the varied applications, features, and impact of these innovative metal fabrication solutions.[Body]1. Precision Engineering Redefined:The company strives to redefine precision engineering in metal fabrication with state-of-the-art technologies. These advancements encompass intelligent robotic systems capable of intricate metal shaping, precise welding and cutting techniques, and advanced computational algorithms to optimize designs. The integration of sophisticated computerized systems with traditional craftsmanship empowers manufacturers to create immaculate metal components, ensuring superior quality and dimensional accuracy.2. Boosting Efficiency and Productivity:By bridging the gap between manual labor and automated production, the company's metal fabrication solutions significantly enhance efficiency and productivity. Cutting-edge robotic systems, equipped with sensors, cameras, and advanced AI algorithms, enable seamless collaboration between human workers and machines. This synergy streamlines the entire production process, enabling faster turnaround times, reduced material waste, and increased throughput. The integration of advanced manufacturing execution systems (MES) allows for real-time monitoring and optimization of production lines, resulting in enhanced operational efficiencies.3. Sustainable Manufacturing for a Greener Future:Recognizing the importance of sustainability, the company places significant emphasis on eco-friendly metal fabrication solutions. Their innovative technologies minimize energy consumption, reduce material waste, and promote recycling of metal components. By leveraging advanced digital simulations, engineers can optimize designs to minimize raw material usage while maintaining structural integrity. Moreover, intelligent robotic systems optimize the use of resources, reducing overall environmental impact. These sustainable practices contribute to an industry-wide shift towards a greener future.4. Diverse Applications and Industries:The versatility of the company's metal fabrication solutions enables their implementation across a wide array of industries. The automotive sector benefits from their precision-engineered metal components, ensuring enhanced vehicle safety and performance. The aerospace industry takes advantage of their lightweight, yet strong, components for aircraft structures. In the construction sector, the company's metal fabrication solutions provide prefabricated components that accelerate construction timelines while upholding safety standards. Various other industries, including energy, healthcare, and consumer products, are also adopting these advanced metal fabrication technologies to unlock new possibilities and improve their product offerings.5. Pioneering Research and Development:The company's commitment to constant innovation is evident through their substantial investments in research and development. By partnering with leading academic institutions and collaborating with industry experts, they stay at the forefront of emerging technologies and industry trends. This dedication allows them to design solutions that cater to the evolving needs of manufacturers across diverse sectors. Their cutting-edge research enables the continuous enhancement of their metal fabrication solutions, ensuring that they remain at the pinnacle of the industry.6. Global Reach and Impact:With a strong global presence, the company's metal fabrication solutions have a far-reaching impact on a global scale. Their technologies are sought after by manufacturers worldwide, leading to collaborations with companies across different continents. By empowering manufacturers with efficient and sustainable metal fabrication capabilities, they play a pivotal role in driving economic growth, improving industrial productivity, and fostering technological advancement on a global scale.[Conclusion]Metal fabrication, the backbone of industrial manufacturing, is undergoing a remarkable transformation induced by the revolutionary solutions developed by this company. Through precision engineering, increased efficiency, and sustainable practices, their cutting-edge technologies are revolutionizing the industry. By diversifying applications, spearheading research and development, and fostering global collaborations, they are elevating metal fabrication to new heights. These advancements not only drive progress but also contribute to a greener and more sustainable future for the industry as a whole.

Discover the Benefits of Injection Moulding for Effective Manufacturing

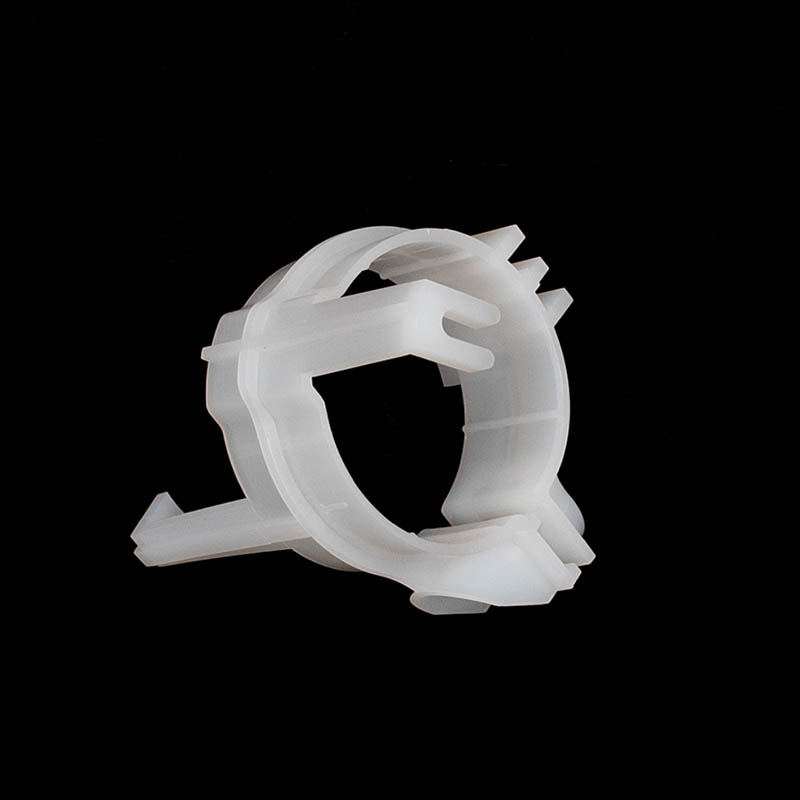

Title: Innovating the Manufacturing Industry: Introduction to Injection MouldingIntroduction:Injection moulding, a revolutionary manufacturing process used in a wide range of industries, is transforming the manufacturing landscape as a highly efficient and cost-effective method. This article aims to provide an insight into the world of injection moulding, with a focus on its significant contributions to various industries.I. Understanding Injection Moulding:Injection moulding, a manufacturing process involving the creation of intricate parts by injecting molten material into a mould, has greatly reshaped the manufacturing industry. Using a combination of high pressure and heat, the molten material is injected into a meticulously designed mould, producing consistent and precise components for various applications.II. Applications and Benefits:Injection moulding finds extensive application across diverse industries such as automotive, medical, consumer goods, electronics, and more. Its versatility is one of the primary reasons for its wide-scale adoption. Some notable benefits of injection moulding include:1. Enhanced Efficiency: Injection moulding ensures high-speed production with minimal raw material waste, making it an efficient process. The moulds used have a longer lifespan, allowing for continuous and consistent production.2. Cost-effectiveness: The ability to produce large volumes of components at reduced costs contributes to injection moulding's cost-effectiveness. This aspect has made it a preferred manufacturing method for various industries worldwide.3. Design Flexibility: Injection moulding enables the production of intricate and complex designs, giving manufacturers unparalleled flexibility in the creation of components. From miniature precision parts to large structural components, injection moulding can cater to diverse design requirements.4. Material Variety: The process accommodates a wide range of materials, including plastics, metals, ceramics, and composites. This versatility enables manufacturers to choose materials based on the specific application, allowing for customized components.III. Industry Use-Cases:Injection moulding has significantly impacted several industries:1. Automotive: Injection moulding plays a vital role in the automotive industry, contributing to the manufacturing of various components such as bumpers, dashboards, interior trims, and intricate lighting assemblies. The cost-efficiency and design flexibility offered by injection moulding have revolutionized automobile manufacturing.2. Medical: The medical industry utilizes injection moulding for the production of disposable medical devices, syringes, respiratory equipment, and surgical tools. The process ensures the production of sterile and uniform components, meeting stringent quality standards.3. Consumer Goods: Injection moulding has transformed the production of consumer goods, ranging from household appliances, packaging materials, electronics, toys, and more. This manufacturing process allows for high volumes of production, meeting the demands of a fast-paced consumer market.4. Electronics: Injection moulding is instrumental in the production of intricate electronic components like connectors, enclosures, and switches. The process ensures precision, stability, and consistent quality, vital for electronic devices' functionality and durability.IV. Company Spotlight: {Company Name}{Company Name}, an industry-leading manufacturer and supplier of injection moulded components, has established itself as a prominent player in the field. With state-of-the-art facilities and a team of experienced professionals, {Company Name} offers innovative solutions tailored to meet the specific needs of its clients.At {Company Name}, the focus lies on research and development to continually improve manufacturing processes and develop cutting-edge designs. The commitment towards sustainability and quality ensures that its products comply with international standards.Conclusion:Injection moulding, a game-changer in the manufacturing industry, combines efficiency, cost-effectiveness, and design flexibility, allowing for the production of high-quality components across various sectors. With its diverse applications and significant benefits, injection moulding continues to revolutionize the manufacturing landscape, offering endless possibilities for innovation and growth in the industries it serves.

Top CNC Plastic Machining Prototype: Breaking Down the Newsworthy Details

Title: Pioneering Plastic Machining Prototype Technology Revolutionizes Manufacturing ProcessIntroduction:In recent years, advancements in CNC plastic machining prototypes have pushed the boundaries of innovation in the manufacturing industry. These cutting-edge technologies have revolutionized traditional manufacturing processes, enabling companies to develop high-quality, precision plastic components. This article explores the recent breakthrough in CNC plastic machining prototypes and its potential to transform the industry.In a bid to stay at the forefront of the rapidly evolving manufacturing landscape, [Company Name], a leader in cutting-edge technology solutions, has recently introduced an unprecedented CNC plastic machining prototype. The prototype is poised to redefine the manufacturing process by offering enhanced precision, efficiency, and cost-effectiveness that were previously unattainable.Unveiling the Revolutionary CNC Plastic Machining Prototype:The groundbreaking CNC plastic machining prototype developed by [Company Name] leverages the latest advancements in machine learning algorithms, robotics, and material science. This combination enables the efficient production of intricate plastic parts, reducing lead times and eliminating the need for expensive tooling.The new prototype incorporates highly sophisticated computer numerical control (CNC) systems that accurately execute commands for cutting, shaping, and fabricating plastic materials. Through meticulous programming and specialized tooling, this technology ensures consistent output, surpassing traditional manufacturing techniques in terms of precision and reproducibility.Unmatched Precision and Quality:One of the key advantages of this CNC plastic machining prototype is its ability to deliver unparalleled precision and product quality. By eliminating human errors and minimizing material waste, this technology ensures consistent and reliable production outcomes. This level of precision greatly benefits sectors such as aerospace, automotive, electronics, and medical, where intricate plastic components are crucial for optimal performance.Efficiency and Cost-effectiveness:The CNC plastic machining prototype significantly reduces manufacturing lead times and costs associated with traditional methods. With its automated processes and rapid production capabilities, companies can obtain functional plastic prototypes within a fraction of the time compared to conventional production methods. This enhanced efficiency translates into reduced project costs, enabling companies to bring products to market faster and gain a competitive edge.Customization and Versatility:The adaptability of the CNC plastic machining prototype allows for customization and versatility in the production process. The technology accommodates a wide range of plastic materials, including ABS, polycarbonate, nylon, and more. Moreover, the precision offered by this prototype enables the fabrication of complex geometries and fine details, catering to various design specifications.Sustainability and Waste Reduction:In addition to the numerous functional benefits, this CNC plastic machining prototype contributes to a more sustainable manufacturing process. Through its ability to minimize material waste and optimize resource utilization, the technology supports environmentally conscious production practices. By reducing the amount of raw material required and minimizing energy consumption, manufacturers can significantly reduce their environmental footprint.Future Implications and Industry Impact:The introduction of this CNC plastic machining prototype represents a transformative juncture in the manufacturing industry. The advanced precision, efficiency, and cost-effectiveness it brings may significantly reshape the way companies fabricate plastic components. These advancements can drive innovation, streamline processes, and empower manufacturers to meet increasing demands swiftly.[Company Name]'s CNC plastic machining prototype signifies a remarkable achievement in pushing the boundaries of manufacturing capabilities. As industries adopt this cutting-edge technology, they can expect greater product quality, reduced costs, and accelerated time-to-market. The future of manufacturing has arrived, promising a more sustainable and efficient era of plastic component fabrication.Conclusion:The development of the CNC plastic machining prototype by [Company Name] has introduced a disruptive force to the manufacturing industry. With unrivaled precision, efficiency, and cost-effectiveness, this technology holds immense potential for transforming production processes and meeting the evolving needs of industries worldwide. As we embrace this groundbreaking technology, we can anticipate a future where manufacturing reaches new heights of advancement, driving innovation and growth.

Understanding the Impact and Prevention of Mold in Air Coolers

[CompanyName] Introduces Innovative Air Cooler to Combat Mold and Enhance Air Quality[City, Date] – [CompanyName], a leading provider of cutting-edge home appliances, is proud to introduce its latest product, the Air Cooler Mold-Removal Edition. This revolutionary air cooler is designed to not only cool the air but also prevent and eliminate mold, providing a healthier and more comfortable living environment.Indoor mold growth is a common issue faced by many households. Apart from being unsightly, mold can also cause various health problems such as allergies, respiratory issues, and skin irritations. Conventional air coolers often exacerbate the mold problem by circulating the existing spores throughout the room. However, [CompanyName]'s Air Cooler Mold-Removal Edition tackles this issue head-on, offering a solution that combats mold while improving indoor air quality.The Air Cooler Mold-Removal Edition incorporates advanced technology to effectively prevent mold growth. It features a state-of-the-art antibacterial filter, which captures and neutralizes mold spores that contaminate the air. This unique filter also eliminates other harmful particles, including dust, pollen, and pet dander, further enhancing the air quality within a space.Furthermore, the Air Cooler Mold-Removal Edition utilizes ultraviolet (UV) light technology to sterilize the air. This UV lamp effectively kills bacteria and viruses, preventing the spread of infectious diseases. By combining multiple mold prevention methods, [CompanyName] ensures a comprehensive and long-lasting solution that sets them apart from other air cooler manufacturers.Aside from its mold-fighting capabilities, this air cooler does an excellent job of cooling the air during warmer months. Equipped with a powerful and efficient cooling system, it quickly lowers the temperature of any room, creating a comfortable and refreshing ambiance. The device also features adjustable fan speeds and oscillation, allowing users to personalize the cooling experience according to their preferences.[CompanyName] takes great pride in the quality and reliability of their products. The Air Cooler Mold-Removal Edition is no exception, as it is built to last and requires minimal maintenance. The removable antibacterial filter can be easily cleaned or replaced, ensuring the continued effectiveness of mold elimination. Additionally, the device is energy-efficient, contributing to both cost savings and environmental sustainability.To make the Air Cooler Mold-Removal Edition even more convenient, it comes with a user-friendly control panel and a remote control, providing easy access to all its functions. The compact and stylish design of the air cooler blends seamlessly with any home decor, making it a perfect addition to bedrooms, living rooms, offices, and other indoor spaces.As part of [CompanyName]'s commitment to customer satisfaction, the Air Cooler Mold-Removal Edition is backed by a comprehensive warranty and dedicated customer support. The company's experienced technicians are available to assist with any questions or concerns, ensuring a seamless ownership experience.[CompanyName] continues to spearhead innovation in the home appliance industry, focusing on creating products that improve the overall quality of life for consumers. The Air Cooler Mold-Removal Edition brings together advanced technologies, remarkable functionality, and aesthetic appeal, offering an all-in-one solution to combat mold and create a healthier living environment.For more information about the Air Cooler Mold-Removal Edition and other innovative products from [CompanyName], please visit [WebsiteURL].About [CompanyName]:[CompanyName] is a renowned manufacturer and supplier of top-quality home appliances. With a commitment to excellence, the company strives to provide innovative and reliable products that enhance the daily lives of consumers. Through continuous research and development, [CompanyName] aims to stay at the forefront of technological advancements in the industry.Contact:[CompanyName][ContactPerson][Phone][Email][Address]